By Jason Matthews

A new technology developed by researchers at the Washington State University promises to aid in dealing with both the world's plastic and fossil fuel problems.

A plane being refueled - Image Credit: Jaromir Chalabala via Shutterstock / HDR tune by Universal-Sci

One major current topic for environmentalists is plastic contamination and, specifically, micro-plastics. Microplastics enter the environment through degraded plastic discarded or dumped, and as micro-beads found in cosmetics.

The global plastic problem

While the destructive results of microplastics on wildlife are well documented, the impact of microplastics on the environment is not yet fully understood.

Evidence is building that microplastics could potentially have devastating consequences for ecosystems and human health as they enter the food chain. See also:

Many countries including, Canada, the USA, Sweden, France, UK, Netherlands, South Korea, Taiwan, and Australia, have already banned the production and use of microbeads for commodities. However, this will not prevent the microplastics from degraded unrecycled waste from entering ecosystems.

The sad truth is that recycling plastic is inefficient, and the resulting material is typically low quality. Current recycling methods involve melting the plastic for reuse, and this only works for thermoplastics. Chemical reaction recycling at high temperatures can be used to produce higher quality material and to recycle thermosetting plastics [plastic that does not melt with heat alone and thus rarely recycled], but this method is too expensive to implement on a large scale.

The inefficiencies and costs involved in recycling mean that, unlike paper and metal, over 90% of plastic is dumped and left to enter the environment.

The nasty stuff gets everywhere, even beaches can be littered with it - Image Credit: David Pereiras via Shutterstock / HDR tune by Universal-Sci

A more efficient process of reusing plastic

The team at WSU, led by graduate student Chuhua Jia, and Professor Hongfei Lin of the Linda Voiland School of Chemical Engineering and Bioengineering, wanted to find a way to reuse a higher percentage of plastic at a much lower cost than existing technologies.

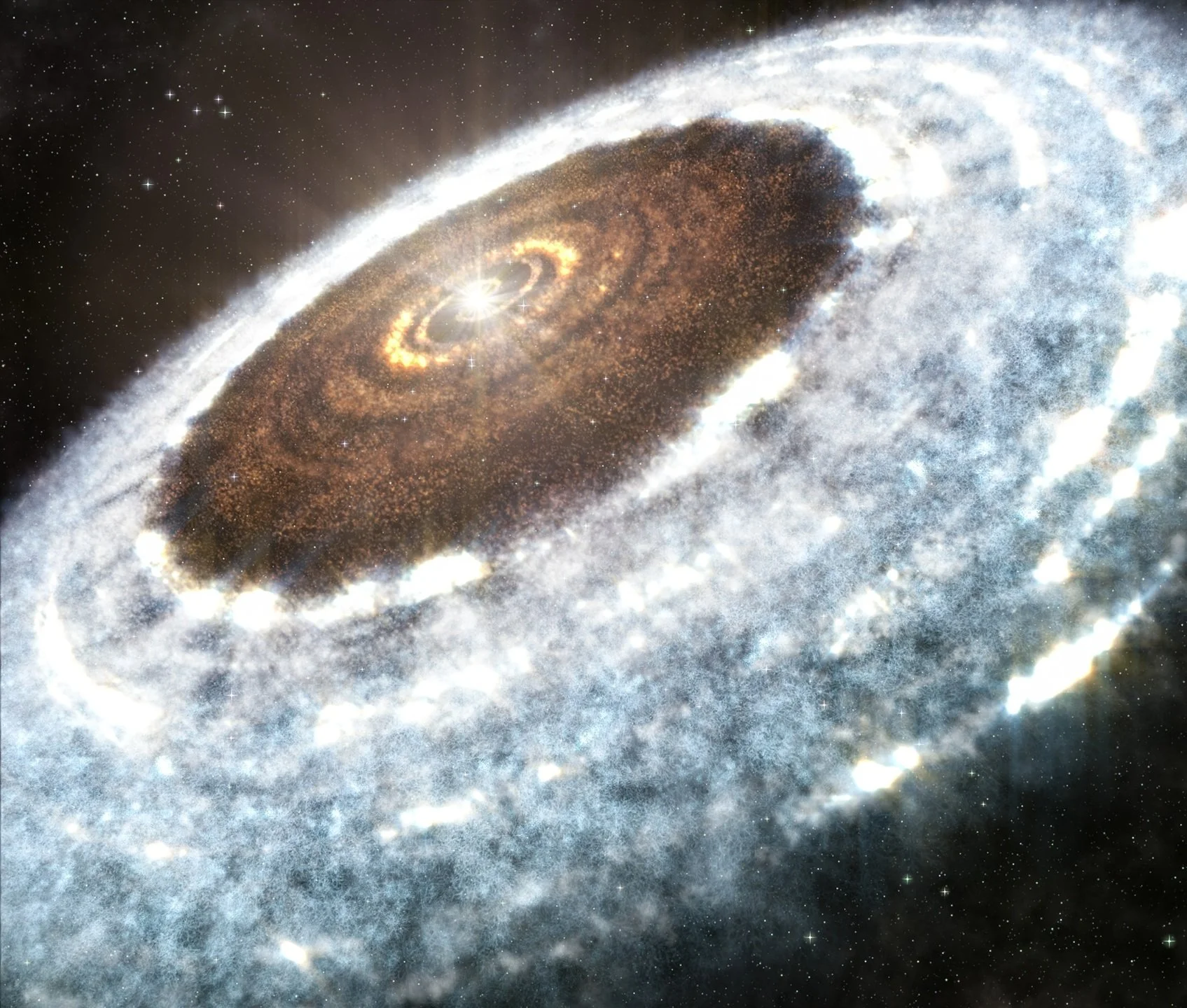

Jia and Lin decided on polyethylene as the subject of their experiments because it is one of the most widely used and makes up most discarded plastic.

Their research led them to use "ruthenium on carbon" as a catalyst. Ruthenium on carbon is an existing product commonly used as a catalyst for temperature-resistant resins and biomass processing. They found that using this catalyst allowed them to reconstitute polyethylene at far lower temperatures than other chemical reaction-based recycling methods. At just 220 degrees Celsius [428 Fahrenheit], they can convert 90% of the polyethylene, in just 1 hr, into jet fuel, high-value lubricants, and other in-demand hydrocarbon products.

Professor Lin explained that the process can be tweaked and adjusted to produce the desired products and can be utilized to recycle other plastics too. He added, "Depending on the market, they can tune to what product they want to generate." --- "They have flexibility. The application of this efficient process may provide a promising approach for selectively producing high-value products from waste polyethylene."

An added benefit from converting plastic to fuel

With oil prices rising and fossil fuels predicted to run out by 2060, this technology promises to help battle our plastic problems while giving industries that depend on fossil fuels some breathing room while developing new alternatives.

The speed of the process, flexibility, and comparatively low running costs mean that the researchers believe they can rapidly scale this technology for commercial use with support from the Washington Research Foundation.

All things considered, this is yet another beneficial addition to our current recycling 'portfolio,' converting a waste product into something useful. Recently scientists also found a novel use for discarded tires, turning them into graphene to make better concrete.

We can only encourage researchers to find more creative ways of managing our global waste and creating functional materials with it.

Sources and further reading:

If you enjoy our selection of content, consider subscribing to our newsletter (Universal-Sci Weekly)

FEATURED ARTICLES: