Scientists from the Massachusetts Institute of Technology developed a mobile desalination unit that weighs less than 10 kilograms and can create clean drinking water without the need for pumps or filters.

The remarkable device results from a journey working on the physics behind underlying desalination processes that took ten years.

Image Credit: nito via Shutterstock / HDR tune by Universal-Sci

The device is the size of an average suitcase, and it needs so little power (approximately 20 Wh per liter of seawater) that a tiny solar panel can energize it.

Another benefit of the unit is that it does not need filters like other small desalination devices. This means that the need for maintenance is significantly reduced, making it ideal for deployment in remote locations like islands or cargo ships.

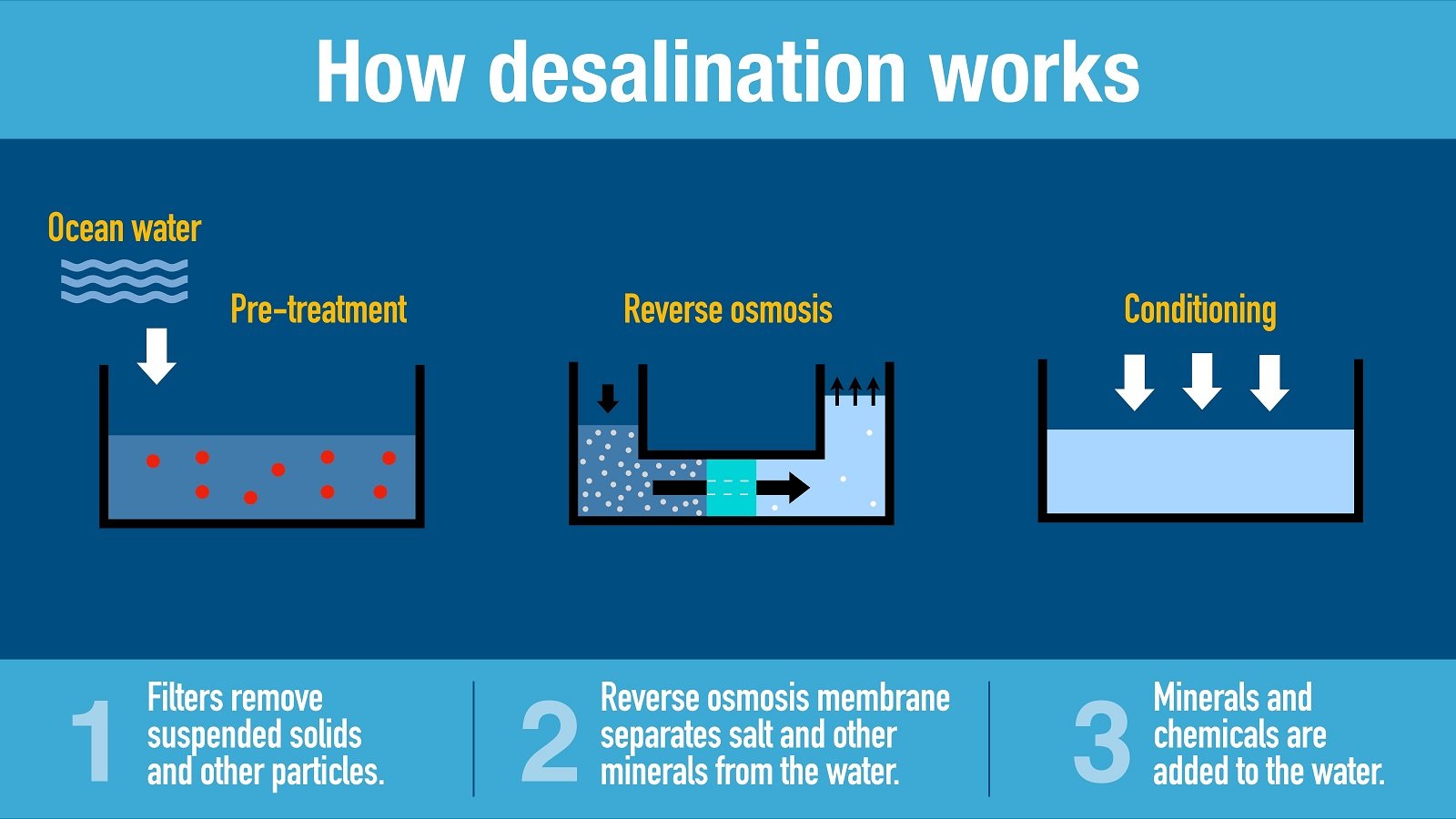

Removing the need for a filter

According to Junghyo Yoon (first author of the underlying research paper), most conventional portable desalination systems need high-pressure pumps to drive water through filters, which are challenging to reduce in size without affecting the device's energy efficiency.

How conventional desalination works (Image credit: Dimitrios Karamitros via Shutterstock)

Instead of filters, the team used a method known as ion concentration polarization (or ICP), which was developed by a group led by professor Jongoon Han (senior author of the paper) more than ten years ago.

Rather than filtering water, the ICP method uses an electrical field to apply to membranes above and below a water channel. Negatively and positively charged particles, like viruses, salt molecules, and bacteria, are repelled by the membranes as they pass by. The charged particles are channeled into an additional stream of water, which is released later.

Both suspended and dissolved particles are removed throughout the process, facilitating clean water to travel through the channel. ICP consumes less power than other procedures since it merely needs a low-pressure pump.

However, ICP does not continuously remove all of the salts floating in the channel. Therefore, the team used a second method known as electrodialysis to eliminate any residual salt ions.

Machine learning was used to uncover the best combination of ICP and electrodialysis modules. The optimum configuration incorporates a 2-stage ICP procedure, with water flowing through a total of six modules in the first stage and then through three in the second stage, followed by a single electrodialysis process. This reduced energy usage while guaranteeing the process remains self-cleaning.

Although some charged particles could be trapped on the ion exchange membrane, they can be easily removed by simply reversing the polarity of the electric field.

The device is the size of an average suitcase and requires very little power to operate - (Image Credit: M. Scott Brauer via Eurekalert)

Future developments

In the future, Yoon aims further to improve the efficiency and usability of the device. At the same time, Han will focus on applying the lessons learned to go beyond simple desalination and developing technology to detect contamination in drinking water more quickly.

As always, if you are interested in more details about the device and the underlying technology, be sure to check out the study published in the science journal Environmental Science & Technology listed below.

Sources and further reading:

Portable Seawater Desalination System for Generating Drinkable Water in Remote Locations - (Environmental Science & Technology)

If you enjoy our selection of content consider subscribing to our newsletter (Universal-Sci Weekly)

FEATURED ARTICLES: