Coral reefs, sometimes dubbed the rainforests of the sea, are underwater ecosystems vital to numerous plants and animals. They form some of the planet's most diverse ecosystems.

According to the World Resources Institute, about three-thirds of coral reefs around the world are endangered. Because of the unprecedented reef die-offs throughout the world, coral reef restoration has been getting more and more attention in the last few decades.

Sadly, protection and restoration efforts have had mixed results. However, scientists think that coral restoration can both be simplified and done faster using modern 3D printing technology.

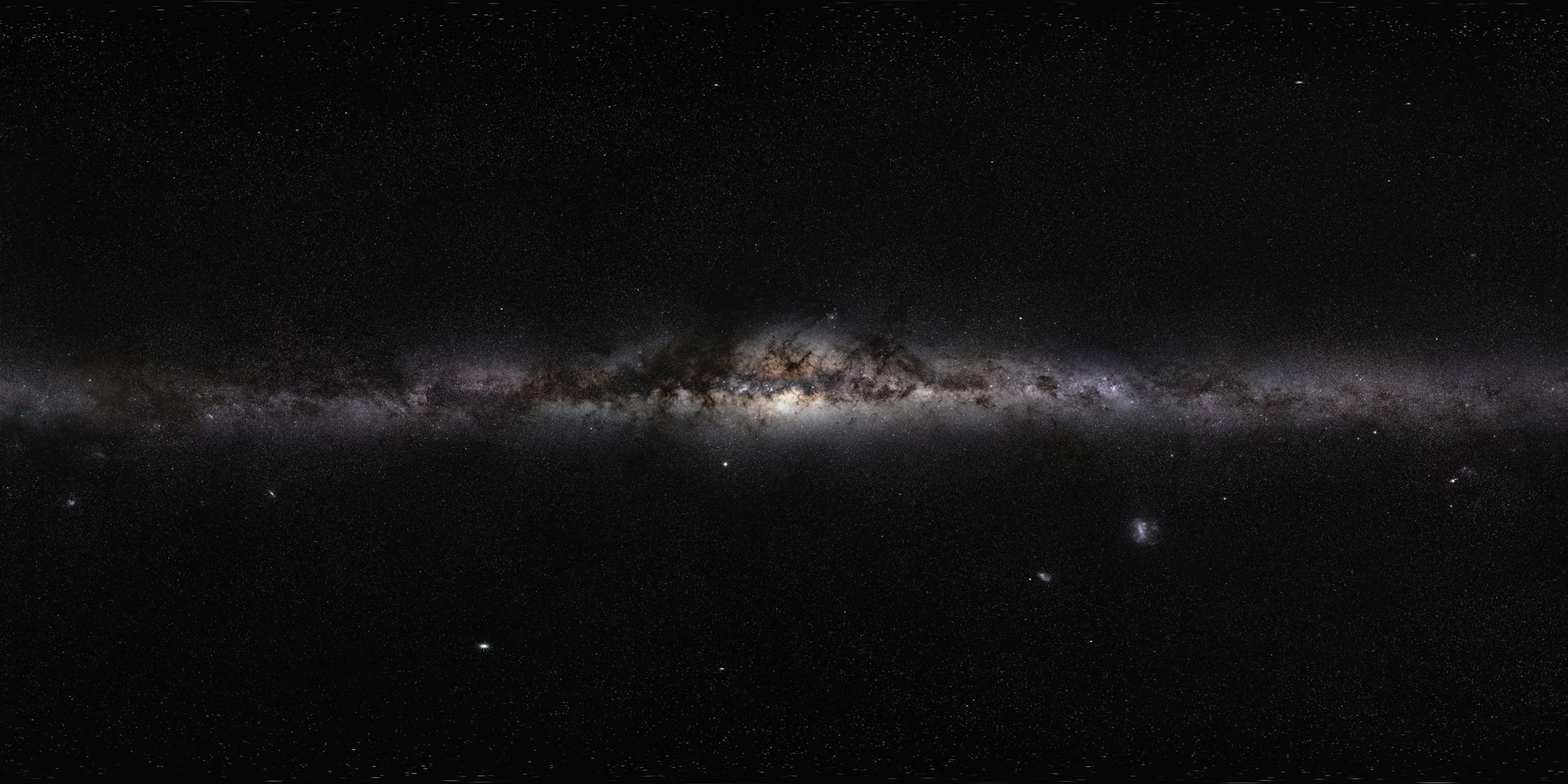

Coral reefs claim less than 0.1% of the ocean floor but provide home to about 25% of all marine species - Image Credit: Borisoff via Shutterstock / HDR tune by Universal-Sci

Up until now, reef restoration efforts have mainly employed metal frames or concrete blocks as backings to promote coral growth. Unfortunately, these types of methods are extremely slow as corals place their carbonate skeletons at speeds of mere millimeters per year.

A team of researchers is examining the idea of speeding up the aforementioned process by using 3D printing technology. 3D printing has matured a lot over the past few years, making the technology more viable for many applications.

According to Hamed Albalawi (coauthor of the study), modeled or printed calcium carbonate surfaces allow for faster growth of coral microfragments as they don't require building a limestone framework underneath. Essentially the idea is to give corals a head start allowing the reef to recover more quickly.

The concept is not new. Scientists have tried various ways of printing coral support structures in the past. The caveat for these endeavors was the fact that most of them utilized synthetic substances.

The new effort is designated 3D CoraPrint. 3D Coraprint employs sustainable and environmentally friendly "calcium carbonate photo-initiated ink," a.k.a. CCP. Initial tests in aquariums revealed that this material is non-toxic, although further long-term research is needed for final confirmation.

Unlike previous methods, which rely on passive colonization of the printed support structure, 3D CoraPrint begins the colonization process by connecting coral microfragments to the printed skeleton. It also has two different printing processes, both of which begin with a scanned model of a coral skeleton.

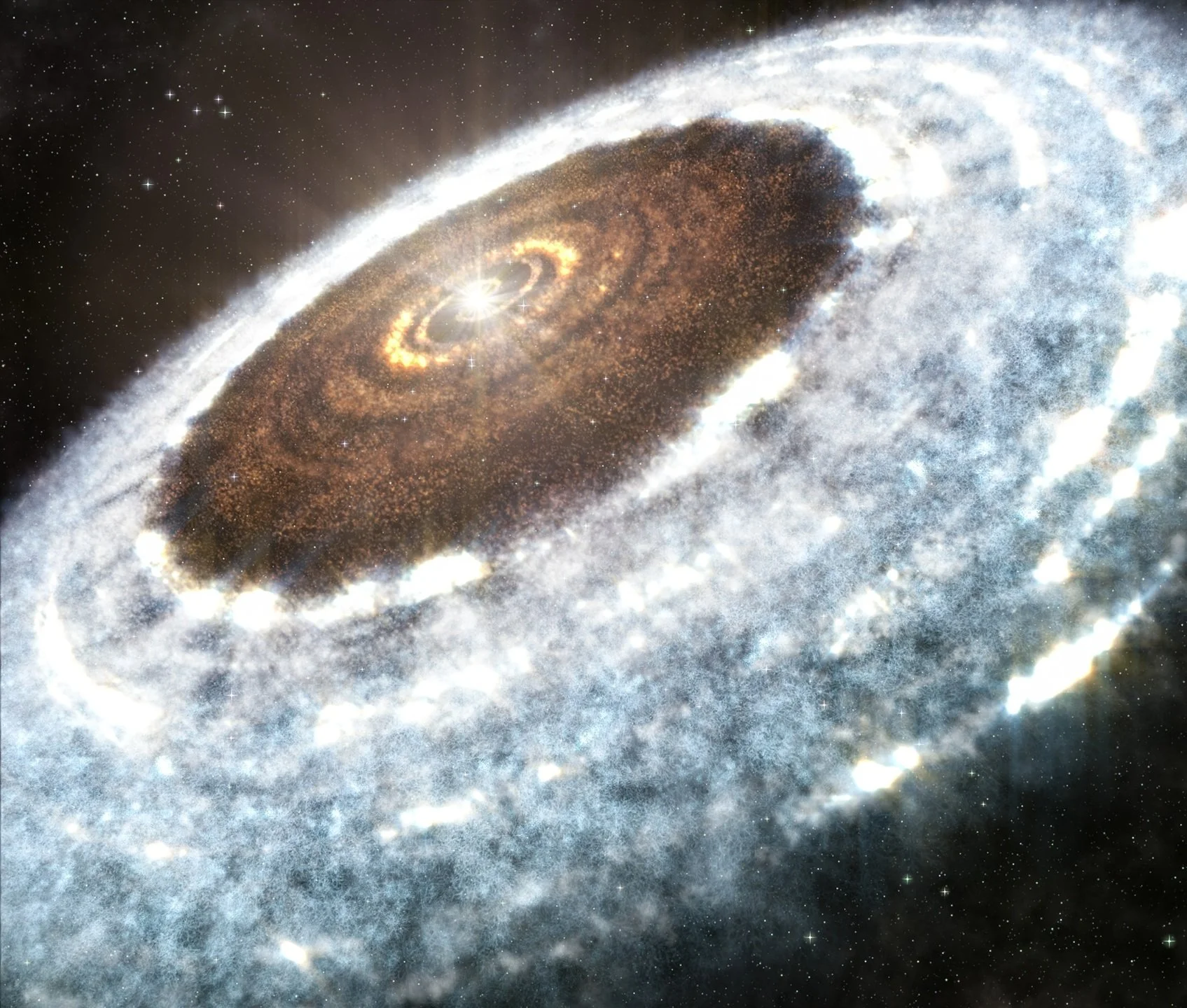

Calcium carbonate surfaces that corals can grow on, which may speed up coral restoration - Image Credit: 2021 KAUST; Anastasia Serin.

With the first approach, the model is printed and gets used as a silicon mold. That mold will be filled with CCP ink to produce the final structure. The second method is printing the structure directly with CCP ink.

Each of these methods has its own advantages and disadvantages. The benefit of producing a mold is that it creates a structure that can be reproduced quickly in a simple manner. However, the disadvantage is that its size is limited by the curing process.

Direct printing with CCP ink has the advantage that it allows for a greater degree of customization and larger structures. However, its disadvantage is the lower resolution and slow printing speed.

Study coauthor Zainab Khan explains that it is possible to get both the flexibility and mimicry of what already exists in nature with their methods. It is the team's goal to facilitate that.

If you are interested in a more detailed overview of the printing methods, be sure to check out the paper published in the scientific journal ACS Sustainable Chemistry & Engineering, listed below.

Sources and further reading:

Reefs at Risk Revisited (World Resources Institute report)

Sustainable and Eco-Friendly Coral Restoration through 3D Printing and Fabrication (ACS Sustainable Chemistry & Engineering)

Bio-inks are the key to amazing new medical applications for 3D printing (Universal-Sci)

Scientists find a clever solution to substitute ivory (Universal-Sci)

If you enjoy our selection of content, consider subscribing to our newsletter - (Universal-Sci Weekly)

FEATURED ARTICLES: