Great news for people with a needle phobia! A team of researchers at Stanford University and UNC-Chapel Hill have developed a groundbreaking vaccine patch that can be manufactured with a 3D printer.

Perhaps even more exciting is the fact that, according to preliminary research, the immunological response from the vaccination patch was ten times bigger than the immune response resulting from a conventional vaccine shot administered into an arm muscle with a needle injection.

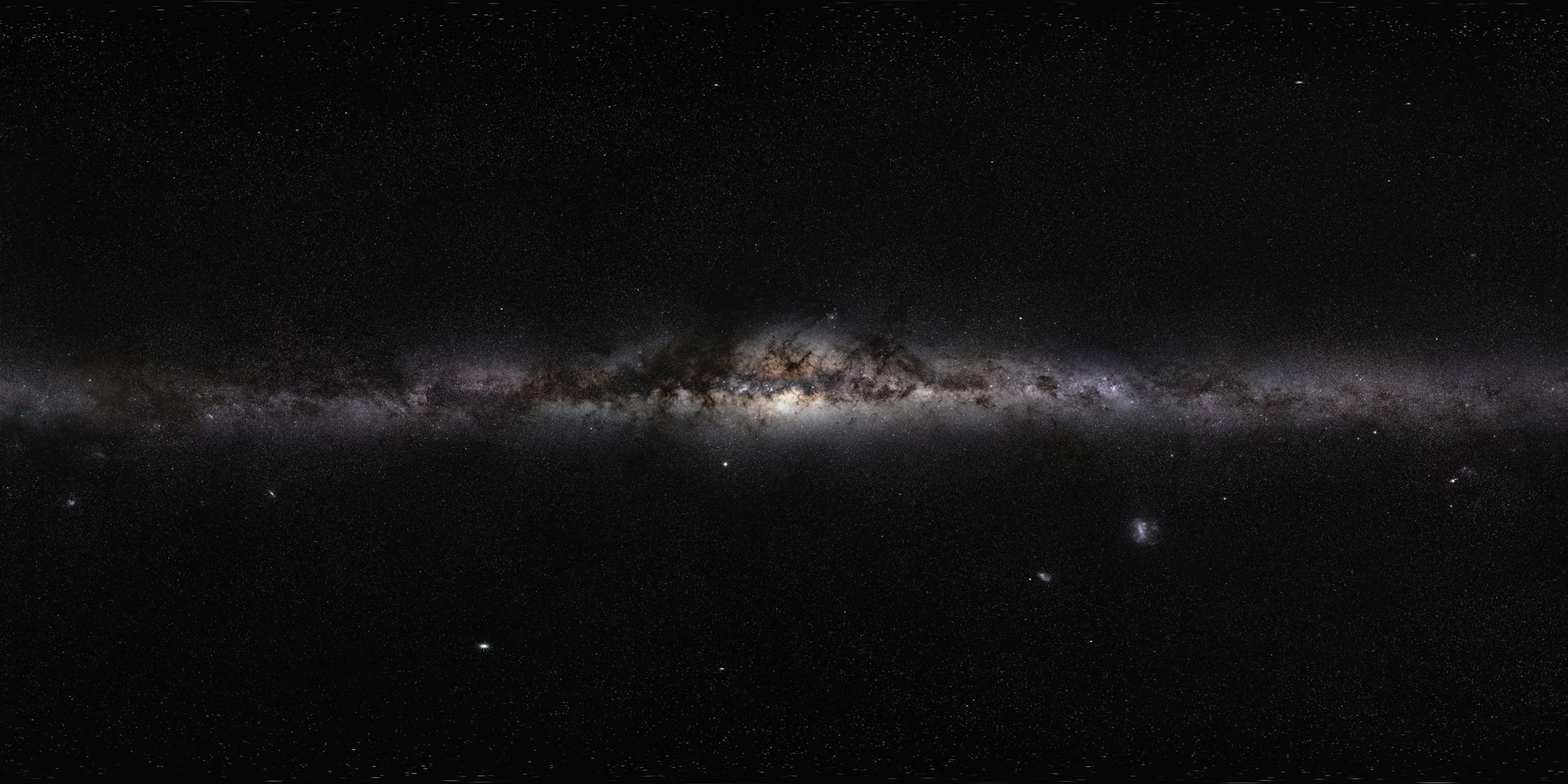

A closeup of the 3D printable vaccine patch. It dissolves into the skin to enhance immunity - (Image Credit: University of North Carolina at Chapel Hill)

The secret is to put the vaccination patch directly to the skin, which contains immune cells that these vaccines are designed to target. Study results show the vaccine patch generated a significant T-cell and antigen-specific antibody response that was far more prominent than a subcutaneous injection delivered under the skin

Although vaccine patches have been researched for many years, this new study eliminates several contemporary difficulties. Chief among these is the ease of customization. With the intelligent use of 3D printing technology for the production and customization of microneedles, a variety of different vaccine patches can be developed at a fast pace.

The benefits of a vaccine patch versus a conventional vaccine jab

The simplicity and efficiency of a vaccination patch pave the way for a new method of delivering vaccines that is painless and less invasive than a needle injection. On top of that, it allows for self-administration, eliminating a host of logistic problems because people will no longer need to visit a doctor's office or health clinic to receive a jab.

The patches are also very effective when it comes to dosage. The enhanced immune reaction will allow providers to be more economical with dosage, which means less vaccine is needed to vaccinate a larger number of people.

Yet another benefit of 3D printed vaccine patches is that they don't need to be refrigerated or frozen, making it a lot easier for them to be shipped around the world.

Vaccine transportation will be a lot easier without the temperature requirements - (Image Credit: Elzbieta Krzysztof via Shutterstock / HDR tune by Unviersal-Sci)

How vaccine patches are produced

It is very difficult to modify microneedles for diverse vaccine types. According to author Shaomin Tian, these problems, combined with manufacturing difficulties, have arguably restrained the field of microneedles for vaccine delivery.

Most microneedle vaccines are manufactured with master templates to make molds. Nevertheless, the molding of microneedles is not very adaptable, and disadvantages include decreased needle sharpness during replication.

"Our approach allows us to directly 3D print the microneedles which give us lots of design latitude for making the best microneedles from a performance and cost point-of-view," Tian said.

The researchers hope that their innovation will create a foundation for an accelerated global deployment of vaccines.

If everything goes well, the patches may also lead to a higher vaccination coverage as the increased effectiveness, and the elimination of a needle could convince people who are on the fence about vaccination to get one.

The study's lead author, Dr. Joseph M. DeSimone, stated that one of the most important lessons learned from the global epidemic is that scientific and technological innovation may make or break a worldwide response.

Let us hope this breakthrough will generate a giant leap forward!

Sources and further reading:

Transdermal vaccination via 3D-printed microneedles induces potent humoral and cellular immunity (Proceedings of the National Academy of Sciences)

Enhancing humoral immunity via sustained-release implantable microneedle patch vaccination (Proceedings of the National Academy of Sciences)

If you enjoy our selection of content, consider subscribing to our newsletter

FEATURED ARTICLES: